Center

HYDRO, Water Turbine Design and Test Center, is an independent research laboratory specialized on water turbines, which plays a critical role in energy production in hydroelectric power plants. Hydro is located within the body of TOBB University of Economics and Technology and carries out activities in various subjects from the design to the testing of water turbines. Reverse engineering, hydraulically and mechanically turbine design, model turbine tests in IEC 60193 standard, turbine manufacturing and field commissioning are some of the working topics. In the center, there are bi-directional pumps suitable for series and parallel operation made of two stainless bodies. Frequency controlled speed adjustment from 5 Hz to 65 Hz can be made in the pump motors. Single pump capacity at the rated operating point; 1 MW power is 80 m drop and 1 m3/s flow rate. There is a generator that provides production up to 2 MW of power, frequency control from 5 Hz to 65 Hz, bi-directional generator and hydrostatic generator bed designed according to special load requirements. Electromagnetic flow meters, differential pressure measuring instruments and many digital and analogue measuring instruments to meet special needs are also available. The center consists of three main units; The relevant units, their activities and their capabilities are described below.

Computer Aided Design Laboratory

It includes the design offices and the high performance computing station. Here, mechanical and hydraulic designs of hydraulic turbines are made. Three-dimensional models are studied parametrically and these models are improved by using optimization methods. Designs are carried out with high capacity workstations. Afterwards, the turbine designs are finalized by completing the simulations at the high-performance computing station for design verification.

|

Computer aided design office |

Turbine Manufacturing Laboratory

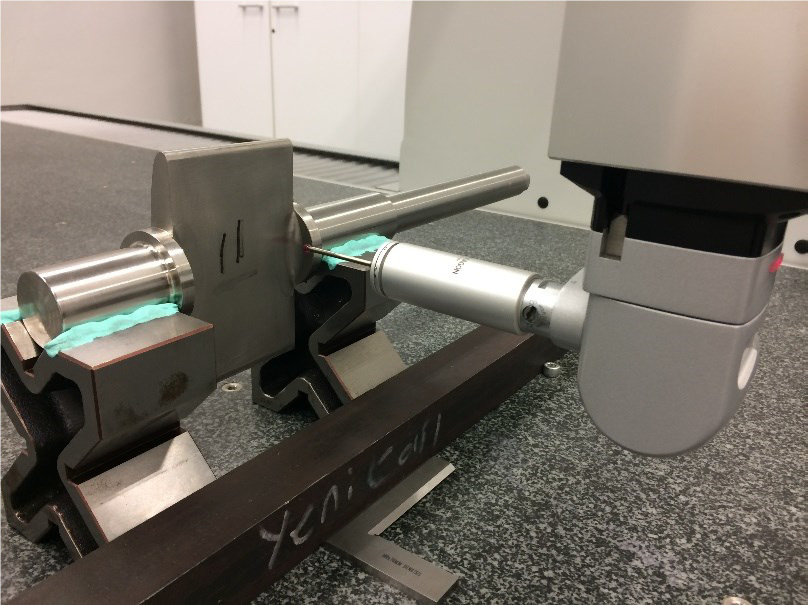

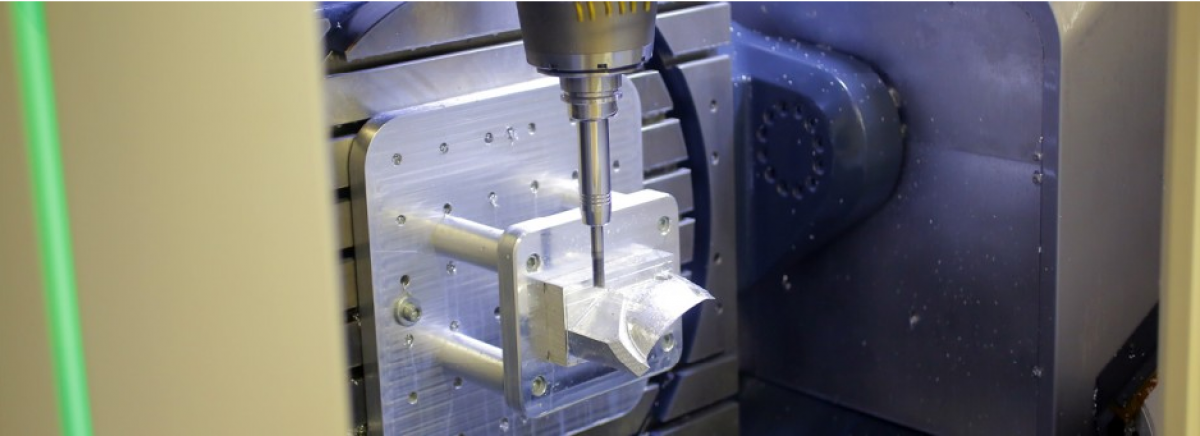

It includes the manufacturing workshop and the quality control office. The workshop is equipped with two computer-controlled production benches (CNC). Models of the turbines where the design has been completed for testing and some full-size turbine components can be produced in-house. Turbine components produced with high precision by technicians are directed to the quality control office after manufacturing. Here, production controls are completed using a coordinate measuring device (CMM) and different measuring equipment.

Water Turbine Model Test Unit

Although turbines go through design and analysis processes using advanced numerical methods, it is of great importance to verify the behavior of them in real conditions with experimental methods, especially in order to prevent unwanted costs in turbines with high power capacity. The Water Turbine Model Test Unit contains the world's highest test power capacity experimental setup established for this purpose. This setup enables the investigation of the performance criteria (flow rate, head, torque, power and efficiency) and cavitation characteristics of the turbine to be used on the scaled-down models with simulation methods. Data from a large number of electronic measurement equipment, all of which can be calibrated within the relevant unit, are instantly transferred to the central control system. These data are observed during the test and various equipment such as motor, pump and bearing are checked by engineers and test studies are carried out. The experimental setup has been designed in such a way that it can perform all kinds of test stages in accordance with the IEC60193 standard. Figure below presents a view of the model turbine and test rig that was assembled prior to testing.

|

MILHES Project Model Turbine (Pre-Test)

|

.png)